Blog about flow meter malfunction

Hello! It is a plumber Momo♪

In this blog, I will explain "Flowmeter malfunction" which is often picked up in our daily work.

Have you ever experienced that the flowmeter has stopped moving even though you are installing it according to the manufacturer's instructions during piping construction?

In this blog I tried to write articles, thinking that one can solve all the troubles of you.

Thank you!☆

(First grade plumber skill: Momo)

流量計の不具合に関するブログ

こんにちは!配管工のももです♪

このブログでは、日頃の業務で多く取り上げられる「流量計の不具合」について解説していきます。

皆さんは配管施工の際にメーカーの取説通りに取り付けているにも関わらず、流量計が動かなくなったなんてことを経験したことはありませんか?

このブログではそんな皆さんの悩みを一つでも解決できたらと思い、記事にしてみました。

宜しくお願いします☆

(一級配管技能士:もも)

Types of flowmeter malfunction

Here, I write about “flowmeter malfunction”(people says that)♪

At first, I want you to know that ”Almost of all cases flowmeter is not wrong, but people often says flowmeter is bad”

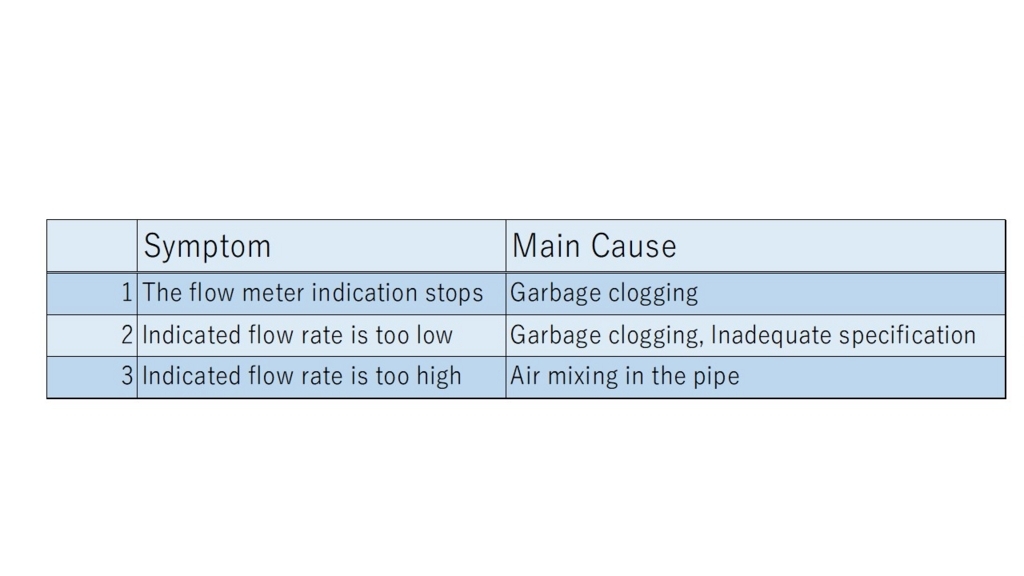

The table below is a summary of symptoms and main causes at the time of trouble which often occurs.

"1. Instruction of flow meter stops" ~Main cause and countermeasure~

Despite the fact that fluid is flowing, pointers and display values do not move in the case of integrating flowmeter, troubles such as instantaneous flowmeter that pointer and display value will not change at 0 can be seen often.

This is mostly due to dust (scales and sludge) accumulating in pipes, dust is clogged in the detection part of the flow meter, and it stops moving.

In this case, according to my experience, if the flow meter is disassembled and cleaned, it will return with about 80% of the probability.

As a countermeasure against such dust clogging, when referring to the instruction manual of the flow meter maker, "installation of a strainer" is recommended, measures such as "① Increase the number of strainers" or "② Make fine mesh" are written.

However, it may be difficult to "① increase the number of strainers" due to restrictions on piping space. Also, "(2) Make the mesh finer", pressure loss will be increased accordingly, so it may not be preferable.

In such a case, as mentioned above, it is safe to disassemble and clean the flowmeter ♪

In the flowmeter, there are many things that can only remove the detection part without removing the piping part, so it is less troublesome than it looks.

"2. Instruction flow rate is low" ~Cause and countermeasure~

Even when the flow meter indicates a small value, there is a possibility of dust clogging as in 1 above.

In that case, let's disassemble and wash the flowmeter according to the manufacturer's instructions as above.

Also, when the specifications differ from the specifications at the time of ordering (the type of fluid, viscosity, temperature, etc are different), the indicated value may be different.

In this case, it is necessary to correct and use the instruction value, use it close to the specification at the time of ordering, etc.

"3. High instructed flow rate" ~Main causes and countermeasures~

When it seems that the instructed flow rate of the flow meter is larger than the actual flow rate, my experience is that the possibility of "air mixing" is the highest.

Especially in the case of piping as shown below, it will be affected by air considerably with probability.

As an air mixing countermeasure, "Air vent valve installation" etc. can be cited.

However, it is important to note here that the fact that the air vent valve is installed does not necessarily mean that the air is out.

In the first place, in the case of negative pressure inside the piping (to the exhaust port side) etc., it is a reality that air enters from the air vent valve.

This is no longer a talk of the flow meter, but since it is a common story, it is necessary to reconsider the piping design sufficiently.

유량계의 결함에 관한 블로그

안녕하세요! 배관공 복숭아입니다 ♪

이 블로그는 평소의 업무에 많은 다루어지는 "유량계의 결함"에 대해 설명하고 있습니다.

여러분은 배관 시공시에는 제조사의 취급 설명서에 따라 설치하고 있음에도 불구하고, 유량계가 움직이지 못하게 된 쓰레기를 경험 한 것은 없습니까?

이 블로그에서는 그런 여러분의 고민을 하나라도 해결할 수 있었으면 좋겠습니다 기사로 보았습니다.

잘 부탁합니다 ☆

(급 배관 기능사 : 모모)

फ्लो मीटर खराबी पर ब्लॉग

नमस्कार! यह एक प्लम्बर बेर है ♪

इस ब्लॉग में, हम "फ़्लोमीटर गड़बड़ी" की व्याख्या करेंगे जो अक्सर हमारे दैनिक कार्य में उठाया जाता है।

क्या आपने कभी अनुभव किया है कि फ्लैमिटर ने चलना बंद कर दिया है, भले ही आप इसे पाइपिंग निर्माण के दौरान निर्माता के निर्देशों के अनुसार स्थापित कर रहे हैं?

इस ब्लॉग में मैंने लेख लिखने की कोशिश की, सोच कर कि आप सभी के सभी परेशानियों को हल कर सकते हैं।

धन्यवाद

(प्रथम ग्रेड प्लंबर कौशल: मोमो)

بلوق على عطل مقياس الجريان

مرحبا هناك! هو سباك البرقوق ♪

في هذه المدونة، سنشرح "عطل مقياس الجريان" الذي غالبا ما يتم انتقاؤه في عملنا اليومي.

هل سبق لك أن واجهت أن مقياس الجريان توقف عن التحرك حتى ولو كنت تثبيته وفقا لتعليمات الشركة الصانعة خلال بناء الأنابيب؟

في هذا بلوق حاولت أن أكتب المقالات، والتفكير في أن أحد يمكن أن تحل جميع المشاكل من كل واحد منكم.

شكرا لك

(الصف الأول مهارة سباك: مومو)