Types of flowmeter malfunction

Here, I write about “flowmeter malfunction”(people says that)♪

At first, I want you to know that ”Almost of all cases flowmeter is not wrong, but people often says flowmeter is bad”

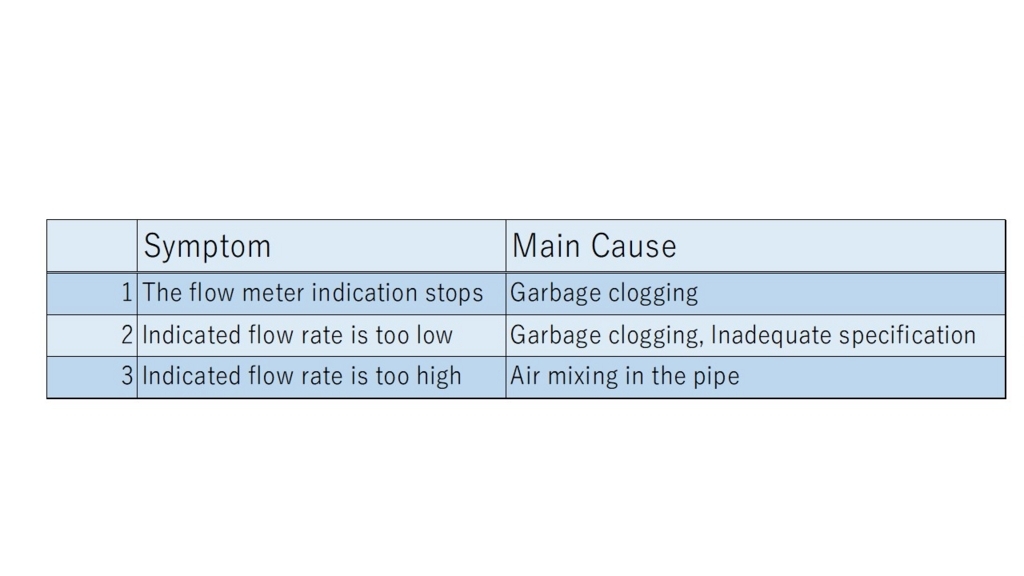

The table below is a summary of symptoms and main causes at the time of trouble which often occurs.

"1. Instruction of flow meter stops" ~Main cause and countermeasure~

Despite the fact that fluid is flowing, pointers and display values do not move in the case of integrating flowmeter, troubles such as instantaneous flowmeter that pointer and display value will not change at 0 can be seen often.

This is mostly due to dust (scales and sludge) accumulating in pipes, dust is clogged in the detection part of the flow meter, and it stops moving.

In this case, according to my experience, if the flow meter is disassembled and cleaned, it will return with about 80% of the probability.

As a countermeasure against such dust clogging, when referring to the instruction manual of the flow meter maker, "installation of a strainer" is recommended, measures such as "① Increase the number of strainers" or "② Make fine mesh" are written.

However, it may be difficult to "① increase the number of strainers" due to restrictions on piping space. Also, "(2) Make the mesh finer", pressure loss will be increased accordingly, so it may not be preferable.

In such a case, as mentioned above, it is safe to disassemble and clean the flowmeter ♪

In the flowmeter, there are many things that can only remove the detection part without removing the piping part, so it is less troublesome than it looks.

"2. Instruction flow rate is low" ~Cause and countermeasure~

Even when the flow meter indicates a small value, there is a possibility of dust clogging as in 1 above.

In that case, let's disassemble and wash the flowmeter according to the manufacturer's instructions as above.

Also, when the specifications differ from the specifications at the time of ordering (the type of fluid, viscosity, temperature, etc are different), the indicated value may be different.

In this case, it is necessary to correct and use the instruction value, use it close to the specification at the time of ordering, etc.

"3. High instructed flow rate" ~Main causes and countermeasures~

When it seems that the instructed flow rate of the flow meter is larger than the actual flow rate, my experience is that the possibility of "air mixing" is the highest.

Especially in the case of piping as shown below, it will be affected by air considerably with probability.

As an air mixing countermeasure, "Air vent valve installation" etc. can be cited.

However, it is important to note here that the fact that the air vent valve is installed does not necessarily mean that the air is out.

In the first place, in the case of negative pressure inside the piping (to the exhaust port side) etc., it is a reality that air enters from the air vent valve.

This is no longer a talk of the flow meter, but since it is a common story, it is necessary to reconsider the piping design sufficiently.